About Mosites Rubber Company

Over seventy-five years ago our founder saw the importance of quality materials and the versatility of synthetic rubber in the future; and because of this, Mosites Rubber Company has been on the leading edge of the rubber industry for decades. We are proud to be known across the nation and in many parts of the world as one of the industry’s leaders.

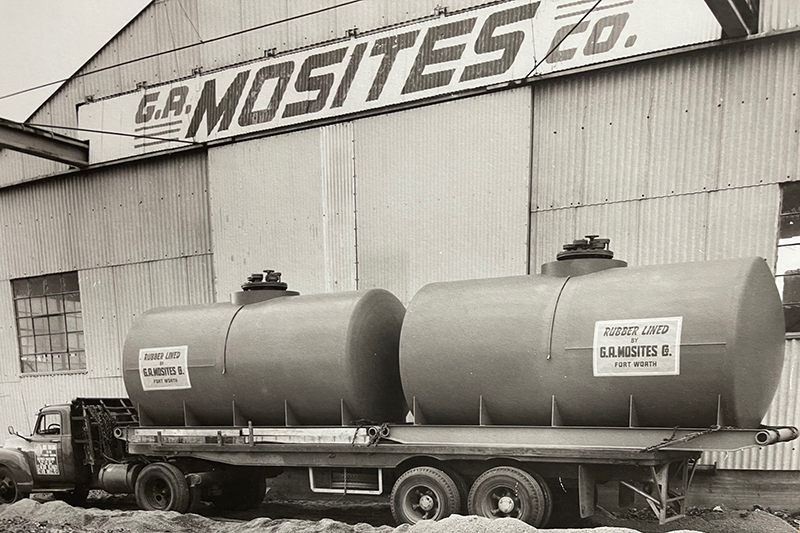

The small manufacturing plant started with just a handful of dedicated employees and a smaller number of customers. But as the company’s reputation and dedication to quality spread, the customer list grew impressively, and many of those dedicated employees stayed with Mosites for many years.

Specializing in Synthetic Rubber Materials

While Mosites started initially making rubber materials for lining large transport tanks and other storage vessels, we soon expanded into the more specialized areas of synthetic rubber, namely forming rubber materials, silicones and fluoroelastomers. We take pride in being able to stock large quantities of these materials, as well as making custom items such as silicone bladders and bonding blankets.

If the material is not on the shelf at the time of the order, it can normally be made and shipped within a three to four week period. And since our manufacturing plant is located in the very busy area of Dallas-Fort Worth, all major carriers are readily available for rapid shipment as our customer chooses.